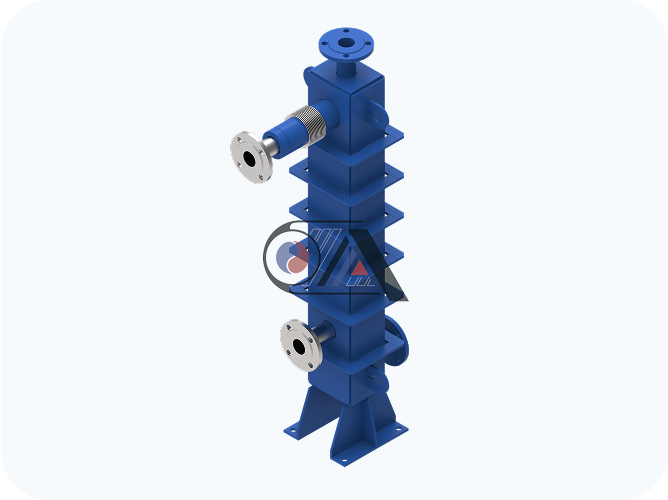

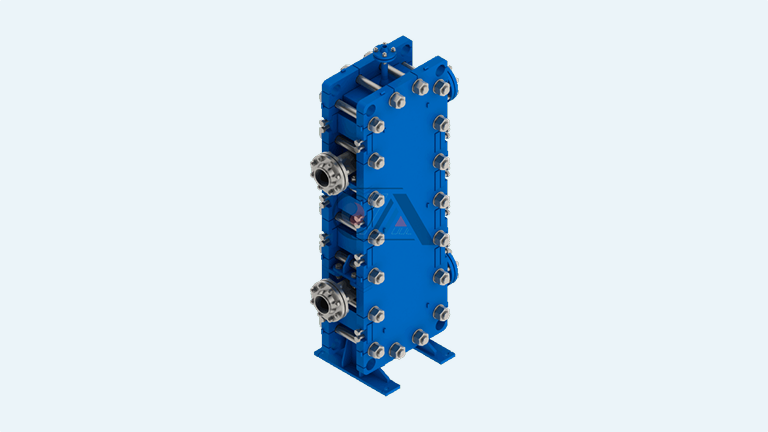

Welded heat exchangers (and their variations) represent the core product of Ankor-Teploenergo. Unlike gasketed models, welded heat exchangers eliminate vulnerable points, significantly expanding their applicability across various industrial sectors. Due to their structural features, these units can operate at extremely high temperatures (up to 650 °C) and pressures (up to 10 MPa).

The key lies in the absence of rubber seals. The plates are perimeter-welded using roller welding, forming sections that are further welded together at the collector openings. Another critical factor is the plate thickness, which for welded heat exchangers starts at 1.0 mm. Additionally, the housing design ensures that no working media escapes into the environment, making these units ideal for aggressive, flammable, or toxic substances.

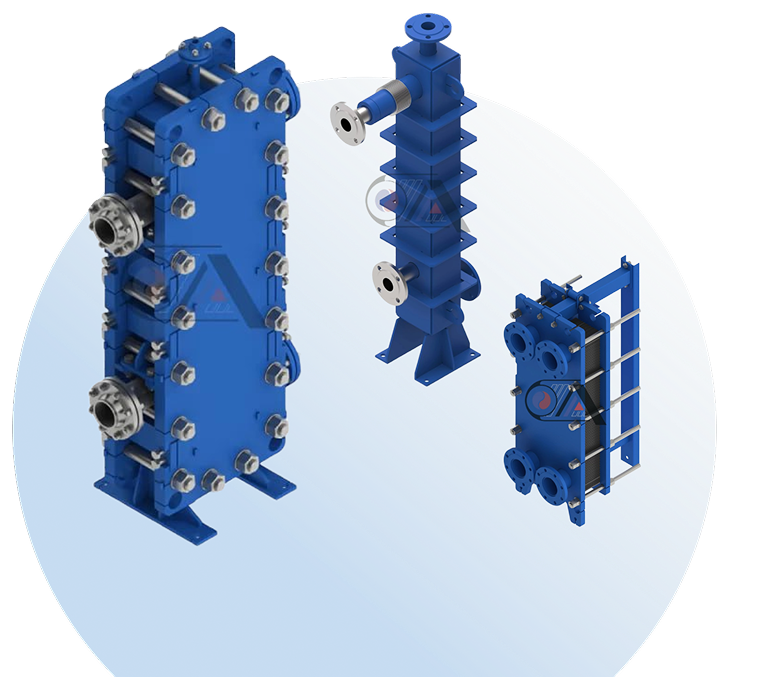

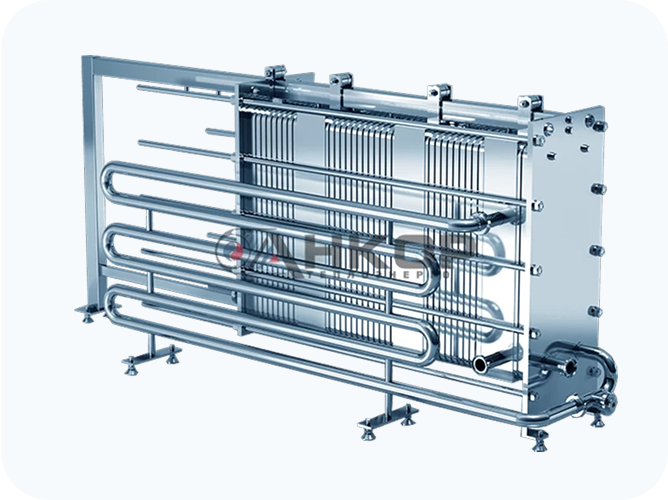

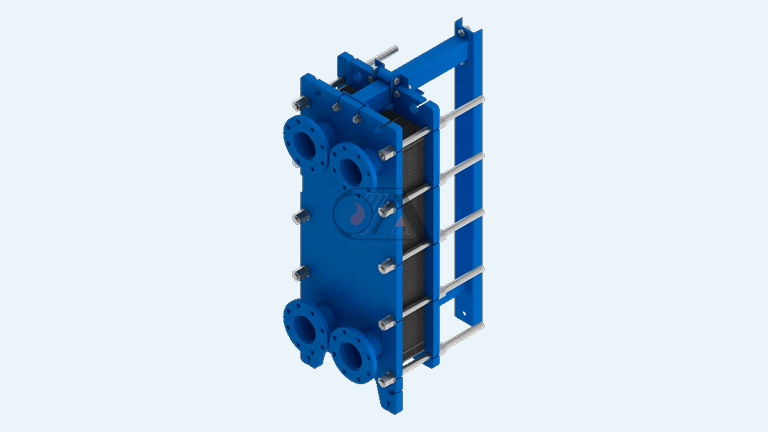

Design of a Welded Heat Exchanger with Removable Shell

Main components of the heat exchanger:

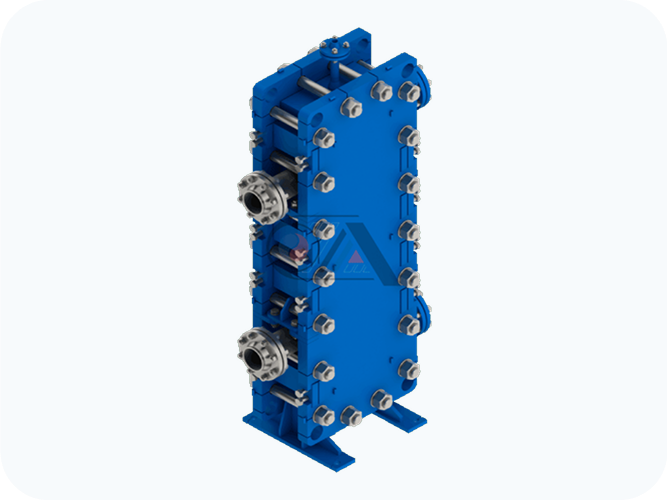

Plate pack: Plates are welded in pairs along the perimeter, forming sections which are then welded together at the collector openings. Thanks to this welded structure, the unit can withstand high pressure without losing thermal efficiency.

Housing: Encloses the plate pack and is one of the most crucial elements of any welded plate heat exchanger. Typically made from low-alloy carbon steel.

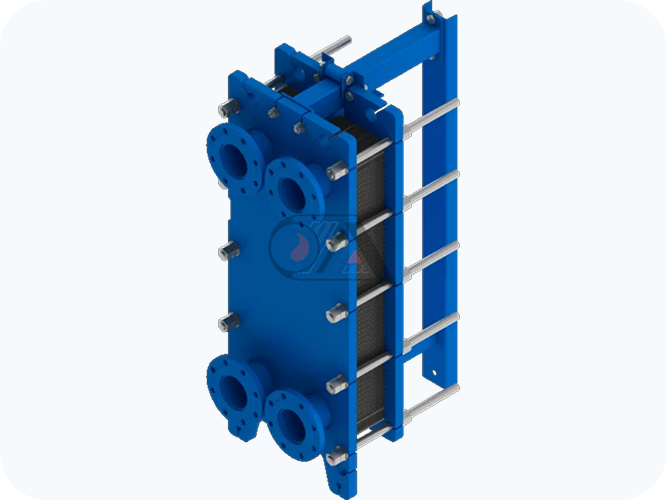

Pressure plates: Allow access to the internal cavity for cleaning. Usually mounted on hinges for easy disassembly. For large or heavy units, they can be mounted on a traverse or monorail, enabling cleaning without lifting equipment.

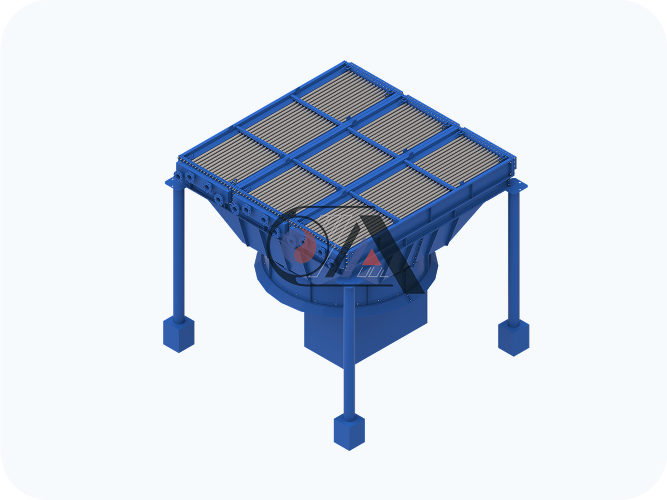

Support structures: Provide stable mounting for the equipment. When multiple units are required, they can be produced as a single module for convenient connection and servicing.

Optional accessories for welded heat exchangers with removable shells may include matching flanges, thermal insulation, spare parts, common collectors, and more.

Operating Principle

The working media enter the unit—one flows into the plate cavity, the other into the shell. Heat transfer occurs between the two media, achieving their required final temperatures. Welded heat exchangers with removable shells are highly efficient. During operation, they can achieve an extremely low temperature difference (as little as 1 °C). This efficiency is due to the corrugated plates that promote turbulence, increasing heat transfer performance.

Unlike gasketed models that use thin plates (up to 0.5 mm) with complex patterns for better heat transfer, welded exchangers feature thicker plates (up to 1.5 mm) with simpler profiles. The channels between plates are clearly visible, making cleaning and maintenance significantly easier.

Materials

Welded heat exchangers with removable shells can be made from a wide range of materials:

Standard stainless steels such as AISI 304, 316, 316L, 321; high-alloy steels like 254 SMO, 1925 hMo, Hastelloy C-276, and even titanium.

Our proprietary die molds also allow for almost unlimited plate size customization, helping you choose the most cost-effective solution.

Applications

Oil and gas industry

Chemical industry

Fat and oil processing

Food industry

Public utilities (HVAC)

Cooling and refrigeration

Metallurgy

Energy sector

How to Choose and Order a Welded Heat Exchanger with Removable Shell

Once you provide the required technical data, our engineers will conduct a free calculation and quote the price of the heat exchanger. After confirming all the details with the client, we manufacture and deliver the unit throughout Ukraine in the shortest possible time.

Why Work with Us?

With over 30 years of experience in the heat exchange equipment market, our company leads the industry thanks to in-house innovations like the welded heat exchanger with a removable shell. Our products and services are trusted by hundreds of clients across Ukraine, Europe, and Asia. We value all our partners and will be happy to review your request to begin a successful cooperation.